Heavy Metal

photograph by pat piasecki

If you had the opportunity to ask an American colonist who the most important person in his village was, without blinking an eye he would point you toward the blacksmith. This master of metal was the sole provider of the tools early Americans depended upon to get through each day. A craft that was passed down only through apprenticeship, blacksmithing has gone the way of the dodo in today’s age of mass production. Some survivors, however, can be found up north at Vermont’s Hubbardton Forge, where modern-day artisans hold close the memory of a bygone era, transforming metal into functional art.

In 1972, college seniors George Chandler and Reed Hampton met in a University of Vermont sculpture class and bonded over a shared interest in handcrafting. Just two years later the artists founded Hubbardton Forge, named for the Vermont town where, out of a drafty 19th-century barn, their company was born. Their first product line included candlesticks, screens for fireplaces, and other accessories, but the pair soon earned a reputation for their unique hand-forged lamps, pendants, chandeliers, and sconces.

The legacy of Chandler and Hampton, now retired, continues today at Hubbardton Forge’s expanded 4,000-square-foot factory in Castleton, where more than 200 employees design, prototype, assemble, and ship customized orders. Inspirations come from far and wide: nature, architecture, and modern art, to name a few, and many of the company’s designers come from fields such as architecture, signmaking, and graphic design. “There’s a ton of experimentation,” says visual merchandise coordinator David Carr. “It’s not exactly throwing darts at the wall and seeing where they fall, but there is a lot of toying with all kinds of elements that could show up in a lamp.”

So how, exactly, do all of those elements come together? Armed with a pair of pliers on a chilly Friday morning in April, forger Annie Gorin gets ready to make Hubbardton’s signature “baskets,” the twirled-steel bulbs that are incorporated into many of the company’s lamps and chandeliers. She pulls a molten steel rod from a forge and locks it into place in an old wood lathe, then proceeds to twist it open with a lever, similar to the way you’d pop open a sleeve of Pillsbury biscuits. Next, Gorin manipulates the bands, hammering and prying them as the metal cools until the basket is symmetrical. “The longer you look at it, the weirder it looks. So you have to pick and choose your battles,” she tells me as I try to emulate her magic.

Parts like these are kitted for the company’s fixtures, each of which is assembled by a single employee from start to finish. Since everything is made to order (local showrooms include Wolfers Lighting and Yale Appliance), customers can decide whether they’d prefer blown or art glass, as well as choose from various finishes and shade fabrics and colors.

Pride runs high inside the factory walls. “Scott and Jeff make the most beautiful forged leaf,” Carr says, pointing to a father-and-son duo who are pounding the tips of steel wands into delicate lanceolate shapes. “It’s one of our most iconic pieces, and it has to be just right.”

photograph by pat piasecki

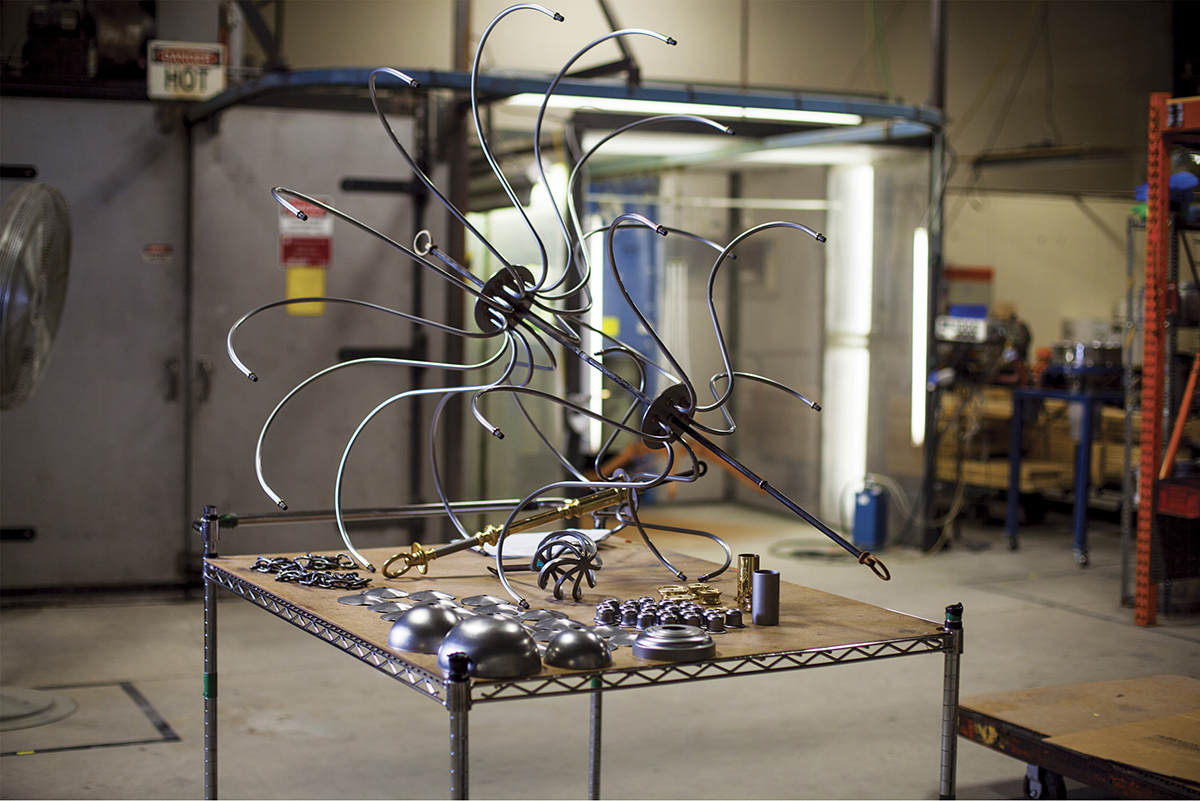

Tools for trade

photographs by pat piasecki

Forger Annie Gorin twists a signature “basket” from molten steel; at Hubbardton Forge, metal is still manipulated with hand tools; an employee works on a large-scale piece in a spray booth.

photographs by pat piasecki

Opposite, each piece is assembled to order; lampshades and finishes are customizable.

photographs by pat piasecki

Baskets come in many sizes and colors.

photograph by pat piasecki

A finished “Twist Basket” table lamp on display.

photograph by pat piasecki

Hubbardton Forge employees come from fields ranging from architecture to graphic design, and many are trained on the job.