What It’s Like to Be a Sailmaker

This orange spinnaker was made by sailmaker Francois Asselin. / Photo by Francois Asselin

Crack open a sailmaker’s toolbox and you’ll find a few key instruments needed to create a sail by hand. Fabric, scissors, and an industrial sewing machine are a few of them, but sailmaker Francois Asselin says the most important tool is an overlooked one—the floor.

“I can only make a sail as big as my floor,” he explains.

Asselin is the head sailing instructor at the Boston Sailing Center on Lewis Wharf. He’s also one of several independent sailmakers in New England. Without the use of computers, Asselin crafts sails of all shapes, sizes, and colors by hand in his Weymouth loft.

After rising real estate prices in 2000 forced Asselin out of his loft in Fort Point, he embarked on a search for another sailmaking space—one free of structural support columns that would prevent him from spreading his sails out on the ground. He lived in South Boston for ten years before finding his ideal space in Weymouth.

“Coincidentally, I found a house with a humungous garage,” says Asselin. He converted the 1,700-square-foot garage (which is almost as big as the house) into his workshop, where he’s been carefully measuring, cutting, and sewing ever since.

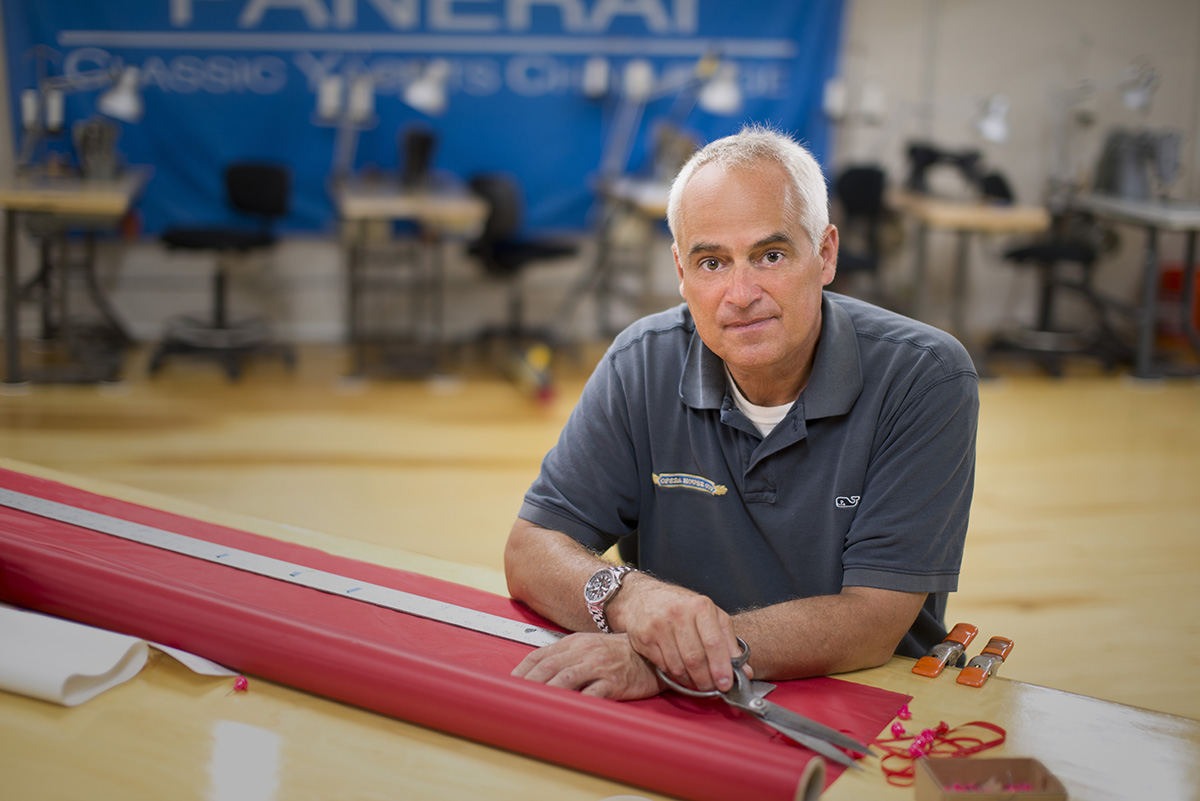

Instead of using CAD, or computer-aided drafting, Asselin employs good old-fashioned measuring tapes and scissors.

“For me, I don’t have that kind of equipment,” he says. “I do it in traditional way.”

Francois Asselin in his studio / Photo by Francois Asselin

He’s crafted almost 20 sails this summer already, which is an impressive feat for an independent maker whose work abounds during the wintertime. Much of his time during sailing season is spent teaching sailors and repairing sails, since most customers opt to order new sails during colder months when they aren’t actively sailing.

Asselin makes sailmaking sound almost easy, condensing the process into a few simple, computer-free steps. First, he obtains the dimensions for the sail by measuring its boat. Then, he creates a two-dimensional plan to scale, assessing the placements of the various panels and parts. Next comes the shape.

“At that point, you just lay it out on the floor,” he says. “You just take strings and lay the outside of the sail, and then you unroll the fabric over that outline that you’ve traced on the floor. Then you pin it on the floor, and start cutting, tracing, and broadseaming the curves.”

Then Asselin assembles the panels, stitches the sail, and polishes it off with corner patches and tape. He decides how the sail will attach to the forestay, or rigging of the boat, and voilà—sailmaking in a nutshell.

The native French speaker is originally from Montreal. He grew up sailing, and moved the United States to obtain a graduate degree in graphic design from Rhode Island School of Design. Asselin worked in design studios in New York City and Los Angeles before opening his own studio in Boston.

His next project was sailmaking. After closing his studio, Asselin decided to hone his sailmaking skills in sail lofts in Newport, Rhode Island, and Marblehead. Eventually he returned to Boston, where he’s been training sailboat novices at the Boston Sailing Center for the past 21 years.

Asselin can’t estimate the number of sails he’s made since he first began 30 years ago. The hours also seem countless, considering it takes about 4 to 5 days to make a main sail, and three days to make a smaller one like a head sail. Each different type of sail requires a different set of decisions, from fabric types to stitching. Asselin has seven industrial sewing machines in his loft, and keeps two at the Boston Sailing Center to use for repairs.

His sailmaking business, FastSailMaker, is part business and part craft, which differs from large-scale sailmaking companies who manufacture sails with a few clicks of a button.

“Eventually someone viewed the business as a business and how to make it profitable as opposed to more individual lofts making sales,” says Asselin. “So in a sense, they’re like Dunkin’ Donuts or McDonald’s or that sort of thing. They’re individually owned and pay a royalty to headquarters.”

While large operations can quickly churn out sails for racers and other boaters who often need replacements, Asselin says he enjoys steering his business the way he chooses.

“(Sailing lofts) are a little bit like hardware stores,” says Asselin. “There are a little bit of mom-and-pop hardware stores, but the big chains have taken over. It’s like a mom-and-pop hardware store against Home Depot.”

He says keeping his small sailing loft afloat gives him freedom.

He explains, “It’s being able to do the projects you want.”

Asselin’s 1,700-square-foot loft in Weymouth / Photo by Francois Asselin